Does Wood Change? Movement

Charles Gibbins

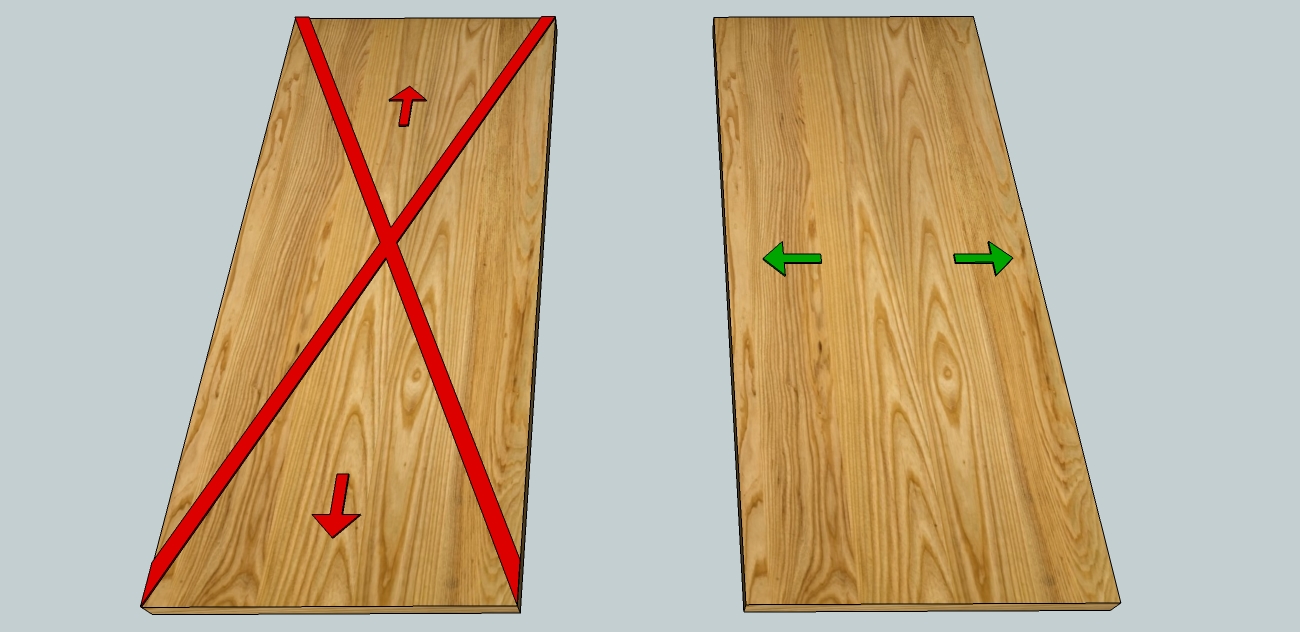

Right, the wood expands against the grain, in the direction of the green arrows

Left, the wood does not expand in the direction of the red arrows

Wood, being an organic substance, is not as consistent as metal or stone. Wood expands mostly based on the moisture in the environment as opposed to temperature variations. Wood continues to take in and let out airborne moisture long after its been turned into furniture. A tree can be considered a large bundle of very tiny straws pulling moisture up from the ground and into the leafy growth. The Sapwood does most of this while the tree is living but the straw structure in the Heartwood are still intact.

A safe assumption is that wood will move 3%-6%. The movement rates depend highly on humidity levels, wood species, and where the board is cut from the log. Wood movement is a general term for the expansion and contraction of a board due to environmental changes, mostly humidity. This movement can exacerbate the internal stresses of the wood causing warping, twisting, and cracking.

After a tree is cut down, it is milled into long planks. These planks are often left outdoors to air dry for 1 year per 1 inch of thickness, until the lumber finds an equal moisture with its environment. It is often finished drying in a large kiln or oven to reduce the moisture even further. Dried lumber is more stable and less likely to crack, bend, twist, or bow and is acceptable for furniture. If the lumber is not dried fully, it is considered Green. Green lumber is often used in home building and outdoor structures and is not suitable for furniture (think construction 2x4's).

Furniture builders must take this movement into account. Most areas of the country run central heating during the winters. Winters can be a dry season and running the central heating only serves to dry out your home even further. This means that Winter may be the time when your furniture contracts a bit and expands in the humid summers. In the Pacific NW, it is quite the opposite, where the winters are truly humid and rainy, while the summers are often dry. This expansion and contractions can damage poorly constructed furniture over the seasons by causing warping, cracking, or it may loosen joints. A great examples is an outdoor table or picnic table, what once was a flat table top, can turn into a warped and unusable mess. We can also see it in wooden doors, where they may operate smoothly at certain times of the year, but stick other time of the year.

Hardwood floors are a common example of expansion and contraction. Certain times of year, hardwood floors may have noticeable gaps in between the boards. This can be an eyesore and and an area that collects dirt and debris. This is why its important when installing new hardwood floors, the floor boards are set inside the room they are to be installed for a minimum of several days.

Why its important to customers. Problems of wood movement might not be immediately apparent, it may take several years for the damage to occur. This is unfortunate, because you've essentially bought a piece with a limited lifespan, or one that will need to be fixed. And we all want our furniture to last for decades and keep its value. Ill expand on this topic in the coming weeks. Thanks for reading this longer post.

Chaz